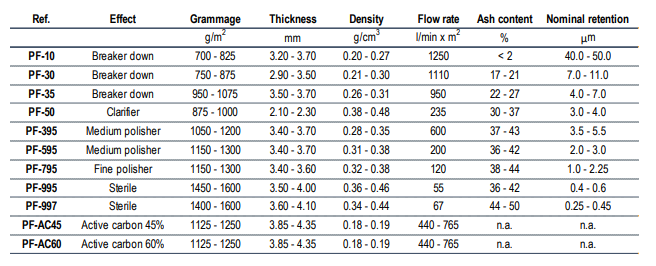

The filtration of liquids through the use of filter presses and filter disks is nowadays a system that is still much in use for: industrial liquids, food, drinks, cosmetics. Filter sheets are made of pure cellulose and cotton fibers, Diatom soil, pearls and polyethylene fibers in some cases. This composition provides to this filtration method some interesting characteristics:

Excellent performance

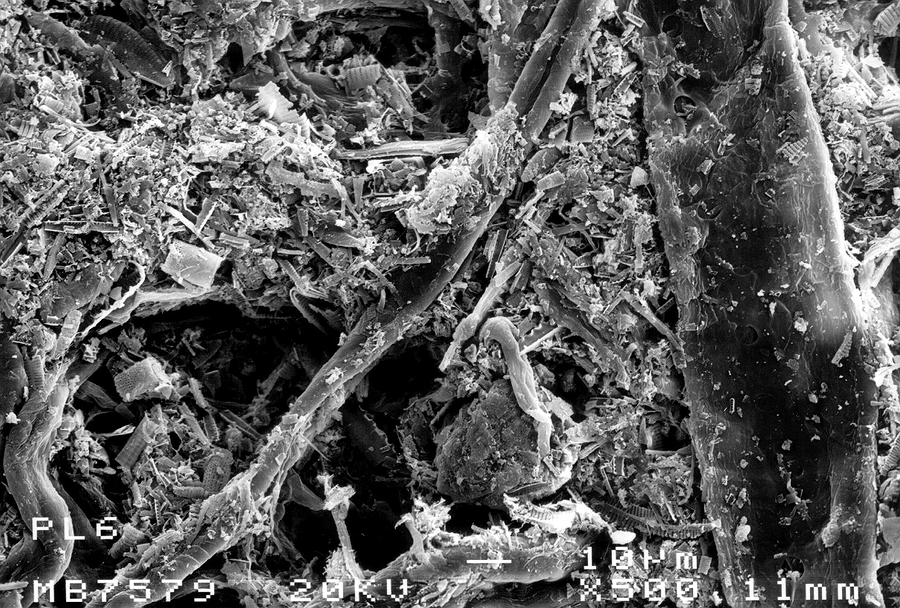

The cellulose structure creates a three dimensional matrix due to the large void volume greater than 85%, allowing passage of high flow.

Retention

Auxiliary materials of the plates increase the retentive effect which, combined with the high positive zeta potential provide polyethylene fibers are retained, also causes small particles and negatively charged colloids.

Quality

The Filtros Anoia, S.A filter disks are manufactured according to the quality system DIN ISO 9001. All specific production parameters are monitored continuously during the whole

manufacturing process.

Resistance

Thanks to the using inert polymers during the production process ensures that these plates are resistant to humid environments, even at concrete temperature

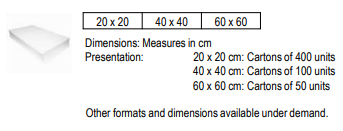

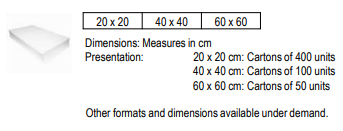

Formats and dimensions